theQuick Fix – Pool

Solve Water Pressure (Spikes) – Clean Filter, Pump/Pump Filter etc.

Inspect the equipment

On an ongoing basis, it is important to keep the pool filter clean. Additionally, it is crucial to address any leaks and replace parts as needed throughout the lifespan of the pool. Monitoring the filter housing gauge can be helpful in the process. To begin this maintenance task, perform a visual and physical. inspection of the Pentair system, which includes the filter, pressure gauge, and blow-off valve. Be vigilant for any sudden spikes in pressure, as well as any obstacles that may impede proper water flow.

Filter Housing, Filter Change, New Gauge and Blower

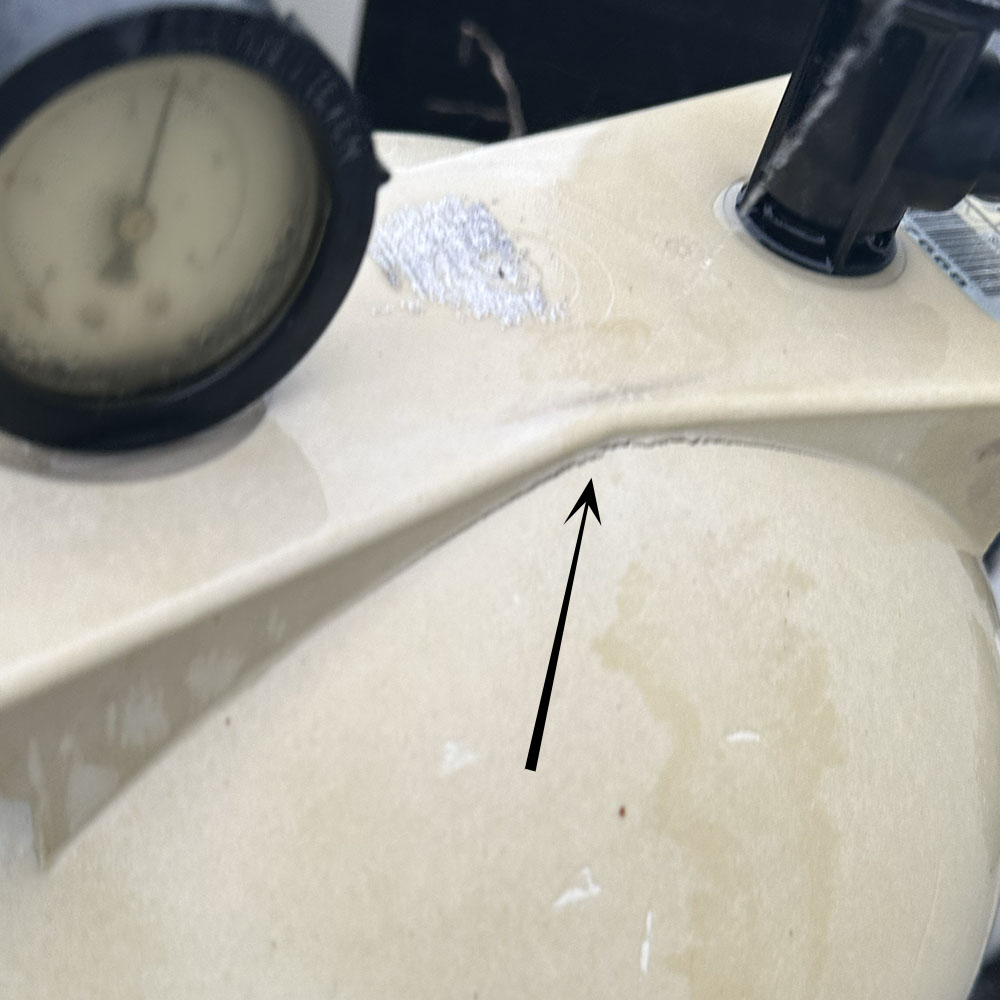

Housing Crack

Filter Change

Clean Filter Insert

Inspect Filter Bottom

Filter Housing, Pump – Water Cycle Ecosystem

Along with the filter gauge, proper filter cleaning is necessary. Keeping the pool clean and free of debris is one thing, but keeping the debris and ‘gunk’ out of the system is another. Let’s focus on the main drain(s), pump filter, filter, filter housing and the return.

Chemicals aside, simple maintenance is key. Keeping the main drain clear, the pump filter and the filter cleaned and free of debris is important (simple, right?). Not too often, but when it does, focus on the filter housing gauge. Pressure can build when the filter is not allowing the recommended ‘flow’ back to the pool via the return. The blow off valve, assuming a generic housing, will help eliminate pressure when needing to power down the pump unit to clean the pump filter and clean, remove or replace the filter.

New Parts

Clean Filter Housing

Place Filter

Infilter Insert

New Filter Top

Filter Housing Issue

Let’s skip ahead to the filter housing issue in our quick fix – pool article. First, here is a generic video showing the process of turning off the pool, removing the filter housing top and gaining access to the filter. Unfortunately, the filter housing top deteriorated due to sun exposure, water, contaminants. Luckily, it didn’t turn into a lost top or a comical scenario where the filter top ends up in a neighbors yard.

After a brief conversation with the pool professionals, it became clear that this is a common point of failure. It can be temporarily patched with epoxy but this is not recommended for this application. In a pinch, do what you can to maintain it, but most of the time, it’s best to get a new top. We will also replace the gauges (these are not due for another day or two, as we have chosen to purchase replacements online).

Going Back to the filter and solving problems along the way will help you better maintain the equipment you have. This has been our approach to working on electronics and technology for our 20 years. Once you’ve learned a your lesson, you typically won’t be to keep notes on your pool filter and make sure to buy the correct filter for your system. Prices will vary as you all know.

Physical and Visual Inspection

Check the filter core, gauges, blow off valve, filter screen (if applicable), and filter. Something is clogging up our filter, possibly algaecide or leftover water coloring solution. It is washable, but for the sake of time, it’s best to replace the filter. This task is not brain surgery, but it must be done correctly. Inspect all parts, clean what you can, and replace the items that are beyond cleaning. Filters and parts deteriorate over time.

While you’re cleaning out the pool, filters and whatever else might be causing problems in and around the pool. Check out our series on pool robots, maintenance, care and more importantly, Maytronic Dolphin robot repairs! Don’t miss out on this series, whether you have a robot, looking to invest into one or have a bot out of order or a Dolphin Down in desperate need of assistance… More content on the way!

In summary, these quick fix – pool tips can be used to inspect all components of the pool pump. Conduct a visual inspection, clean the baskets, filter, filter core, filter housing bottom, and check the water. Balance the water with chemicals as needed, then deploy the pool robot to start the cleaning process.

Like the quick fix format? Check out other quick fix content here such as this disposal problems fix. Like the learn to descale your coffee equipment – pots and machines, fix a toilet float clean. Like this quick pool filter housing and filter fix, try a cell phone charging hack… Check them out!