Nano Mixer Fix

Bloom’n Again, Mixer Back In Action

Tech | Tools – Frother Quick Fix

Quick Fix – Disassemble, Clean, New Batteries…

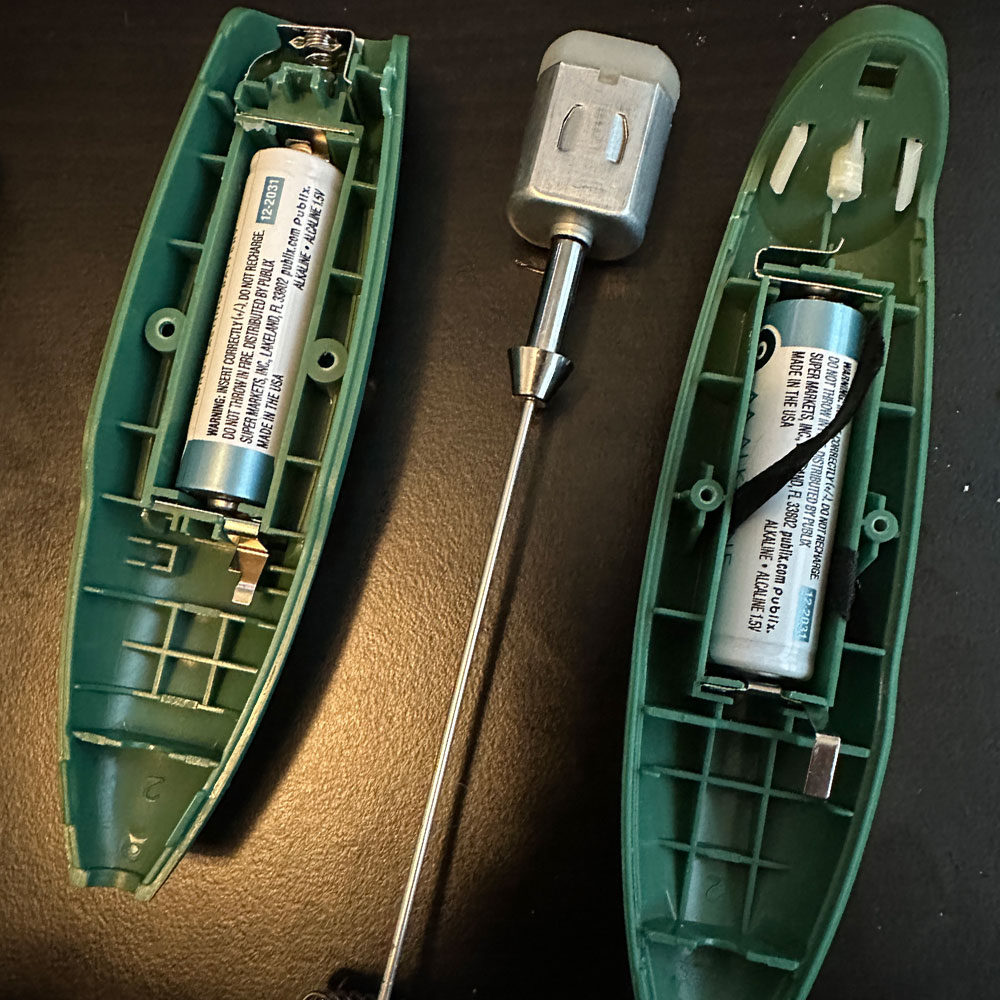

Quickly stir in sugar and milk, mix up your protein powders and fine particulates; all made easy with the Bloom mixer. I wanted to share a quick fix, as our nano mixer quit on us a few weeks back. Typically, the morning and afternoon espresso is ‘cut’ with a few granules of sugar and some half and half… as I get older, the trend has been ‘lighter and sweeter’… any how, here is the internal works of the mixer, teardown – a few screws, clean up, reset the metal prongs and a new set of batteries and we were back in business. Mixing up protein powder, scrambling eggs and espresso/coffee.

Just a note, be sure to keep the lower body (green structural plastic in the picture) dry if you can, there is a bit of a seal there… but better safe than dropping $20 – $40 on a new one. Again, here is the link for the Bloom variety, I think the mixer has been updated since the date of purchase.

We’ve tried the ‘mini blenders’ like the Bullet’s, and the hand blenders, the top of the line so to speak, with the blenders… there are advantages to all, negatives as well. The Bloom mixer is great, now that we got a Quick Fix – Nano Mixer running again. Nice mixer for the small stuff, no need to plug anything in, or clean up pre-made cups etc. Magic Bullet style mixers were great for ‘bullet coffee’*.

Make Bullet Coffee

Never heard of bullet coffee. Make some coffee in a Bodum or Colleti.. or choose your home Coffee Machine. See below. There are a few of the nano/hand mixers on the market, and Amazon can help you find one that fits your budget. I’ve included some below so you can make your own ‘bullet coffee’, with links included…

*Bullet Coffee Recipe: Full Fat Butter, Raw Coconut Oil, espresso/coffee of choice – Nespresso Pods – Tokyo Vivalto Lungo, a few spins of the mixer, and you’re done.

In conclusion, I’ll probably post more about espresso machines, specifically the Nespresso machine. Stay tuned for more. Thanks!