Proper Maintenance And Care

Descale Modern Coffee Machines

Descale with Apple Cider Vinegar

White vinegar or apple cider vinegar works, preferably organic, will work ofr this task. A quick tip: use vinegar to descale coffee machines. The objective is to clean and descale the pipes and water reservoir of a modern coffee machine. For machines, including camp pots and classic coffee pots, vinegar will suffice. For manual types, a mixture of vinegar and baking soda can be helpful. If there are stubborn coffee stains that are difficult to remove, a little baking soda can provide extra scrubbing power.

Typical Coffee Machines Needing descaling

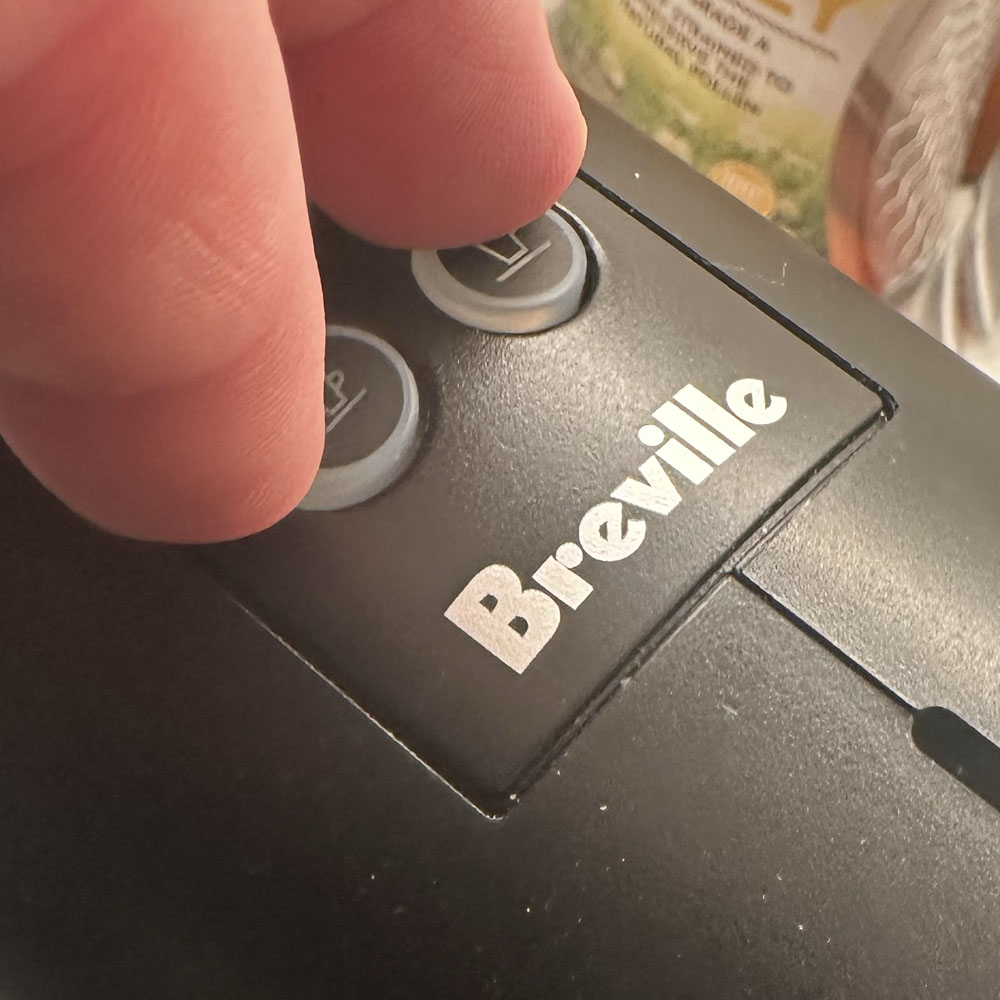

Below, we have two machines, a. Keurig brand Coffee Machine and b. Breville brand Nespresso machine. We hve used both coffee machines and continue to clean them as needed, regularly and thoroughly. Simple monthly cleanings will go a long way.

Keurig Type Machines

Water Reservoir

Interface

Pod Area

Press To Clean

Post Clean

To clean your Keurig (generic) machine, depending on the model you own, pour a mixture of vinegar and water into the reservoir. Choose a cup size and place the cup below the spout, then start the machine. Let the water and vinegar solution run through the machine until it’s all gone. For the next cycles, use only water in the reservoir. I usually run three full cycles: 1. Water with vinegar, 2. H2), and 3. More water. The aim is to ensure that all the vinegar is completely flushed out of the machine, including the small reservoir inside.

Remember, to run the machine as many times as necessary to clear out the vinegar. A small amount of apple cider vinegar shouldn’t cause any issues, assuming no allergies. We’re talking about trace amounts here. Just a disclaimer: I’m not a health professional, nor ram I representing apple cider vinegar or vinegar in any way that suggests health benefits. The vinegar is simply the cleaning agent, replacing store bought chemicals).

Nespresso Type Machines

Visual Inspection

Pod Area

Vinegar & Water

Press And Hold

Ready to Brew

Fresh Espresso

Same process for the Breville (generic) Nespresso machine, caveat, holding the two ‘size’ buttons on the top of the machine..This will turn on the machine and it will run until the water reservoir is empty. I’ve found it easier to just unplug the machine, once it has finished running. Not saying that his is the correct way, just the way I clean the machine.

Ok, moving on, rinse and repeat, the same cycle as mentioned above – 1. water with vinegar, 2. water, 3. water. Run 2 or 3 cycles and your machine should be good to go. If the descale indicator light is on, you may need to run a fourth or fifth cycle. It’s time to clean if the light has been triggered. The cleaning schedule is monthly, sometimes every two months depending on usage. If we use either machine less frequently, it’s important to run the vinegar solution more often to maintain tubes, bungs, diaphragms and fluid mechanical components.

Let’s leave it at that. Some machines will require a K-cup to remain in the machine in order for it to run. You can just use a ‘spent’ cup, no harm in that. I typically make a cup to drink while I clean the machines, so I have a fresh cup if needed. Obviously, this quick tip – descale – is not necessary if you have one of the new machines, a K-cup with a QR code. The level of frustration on the first series, required a K-cup with the stamp.

Side Bar – Coffee Pots, Camp Pots and Manual Brewers

A simple way to keep these vessels clean is by using water, vinegar and baking soda. The reaction between the vinegar and soda is quite fun. I remember making a volcano-like structure in elementary school using the same two chemicals. To clean, grab a sponge or paper rag, place the soda at the bottom, then add vinegar and water. You can pre scrub the soda around the inside of the camp pot for example. Pour in the water/vinegar mixture (hot water where applicable) and scrub the mixture until the soda powder is fully incorporated into the liquid. This process typically only takes a minute. Scrubbing until it’s incorporated acts like the silica grit inside toothpaste, which helps scrub the stained sides, tops, or handles.

If you have a camp coffee pot or percolator, follow similar cycles using vinegar and baking soda to remove the coffee stains, burnt coffee, coffee grind oil/debris and residue. Using vinegar as a quick tip – to descale your coffee pots and machines is key. The baking soda acts as a scrubbing booster while the vinegar’s acid breaks down those hard-to-clean coffee spots. The same method can be used on pots and pans, but I’ll save that for another post. Holiday time seems to be an appropriate time and place.

Like the quick fix format? Check out other quick fix content here such as this disposal problems fix. Like the learn to descale your coffee equipment – pots and machines, fix a toilet float, clean and fixpool filter housing and filter problem or try a cell phone charging hack… Check them out!