Pre-Assembly, Rebuild In Progress

Assembly & Direct Drive Rebuild, 2

Lab Work – Rebuild In Progress, Part 2

A few steps forward now, we pick up with the bold on extruder assembly and assembly backplate here in part 2. So, we continue the rebuild in progress, part 2

Focus, Removal Of Bowden Drive

Fully Assembled

Remove Housing

Extruder

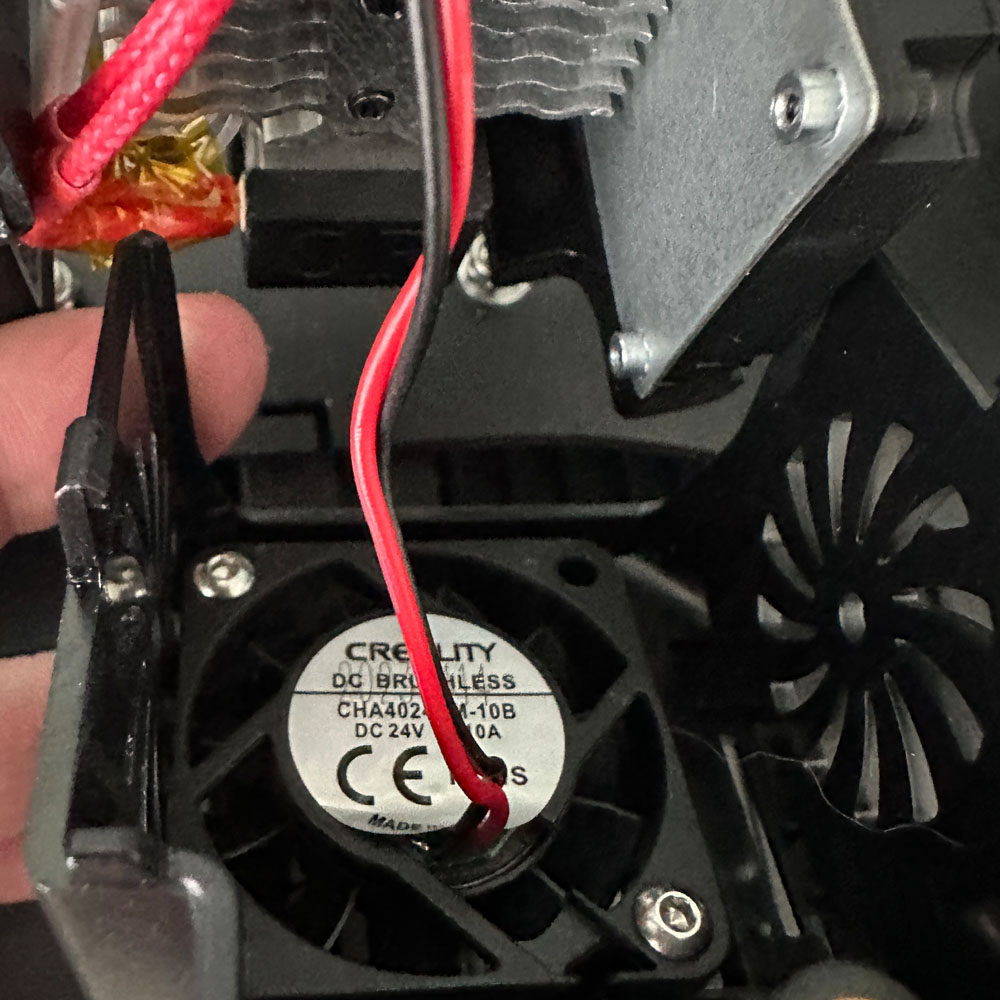

Remove Fans

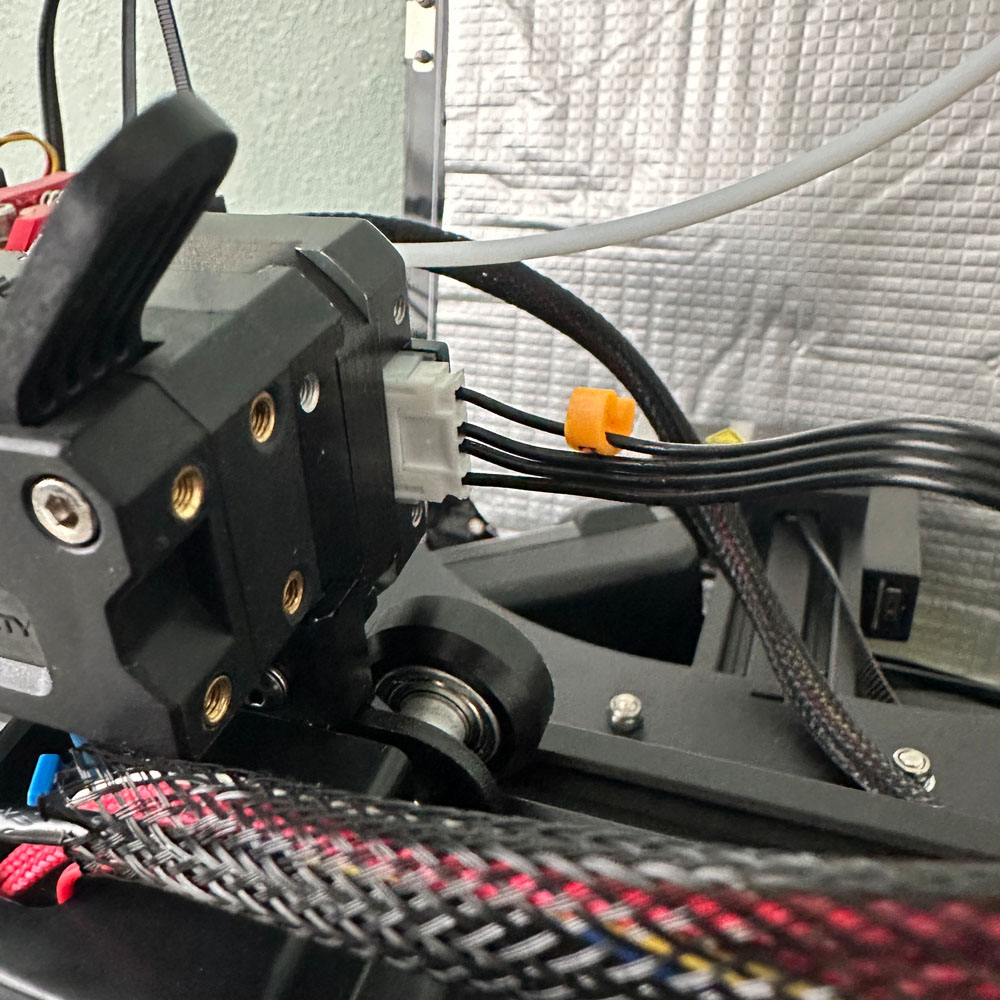

Remove Extruder

Disassembly

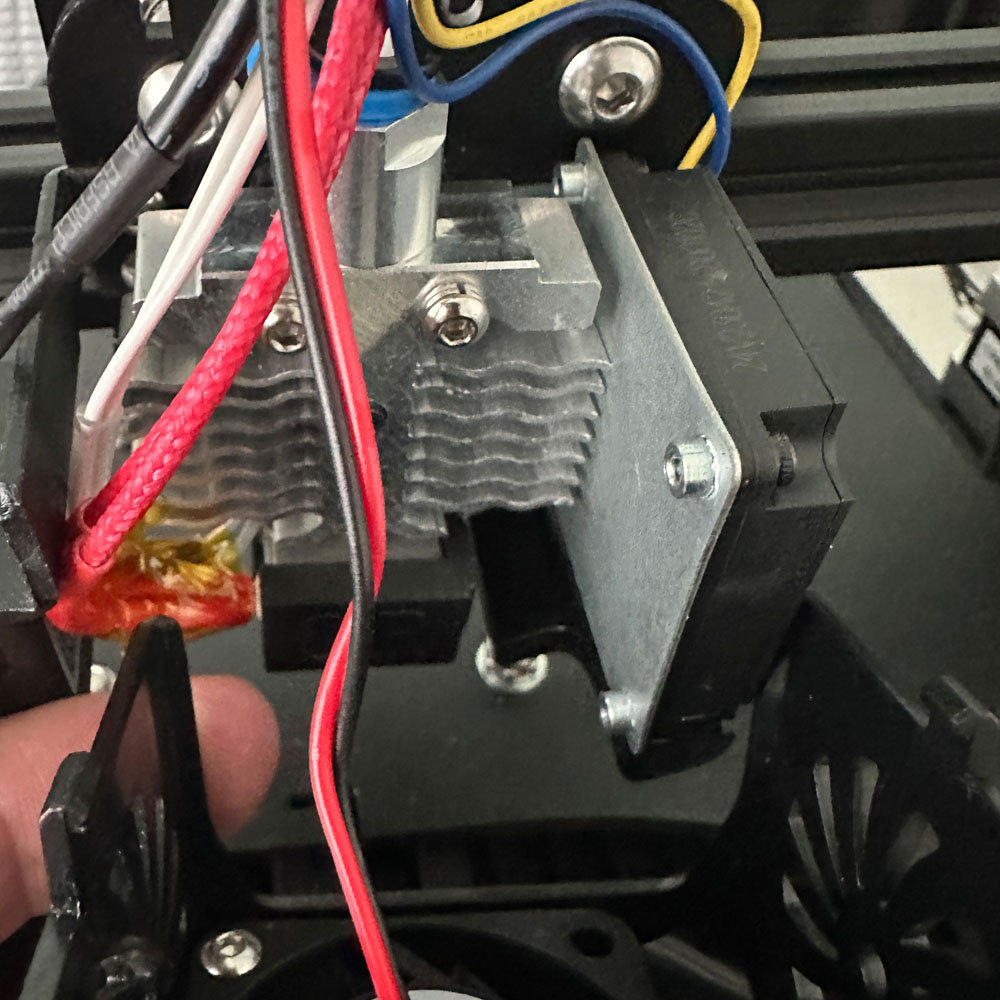

Hot End

Clip Tubing

DD To Extruder

DD Tubing

Motor Clips

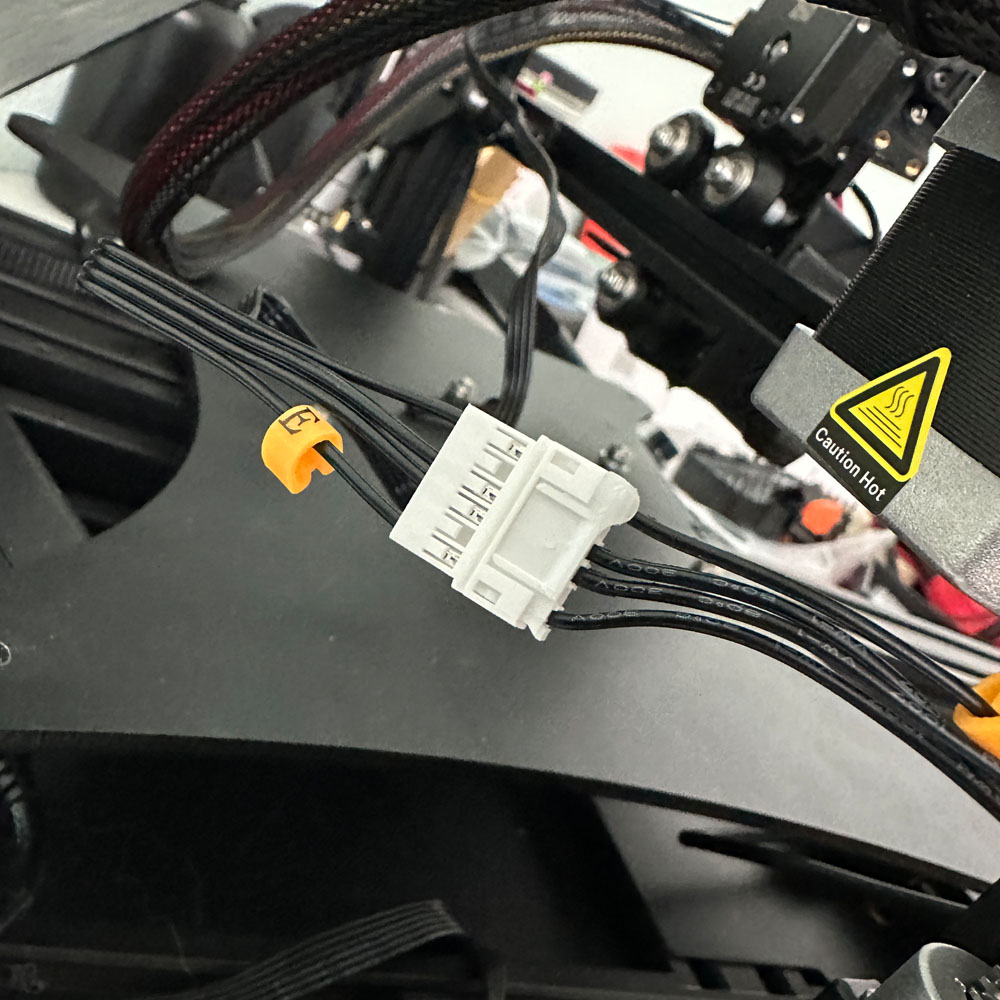

Motor Control

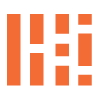

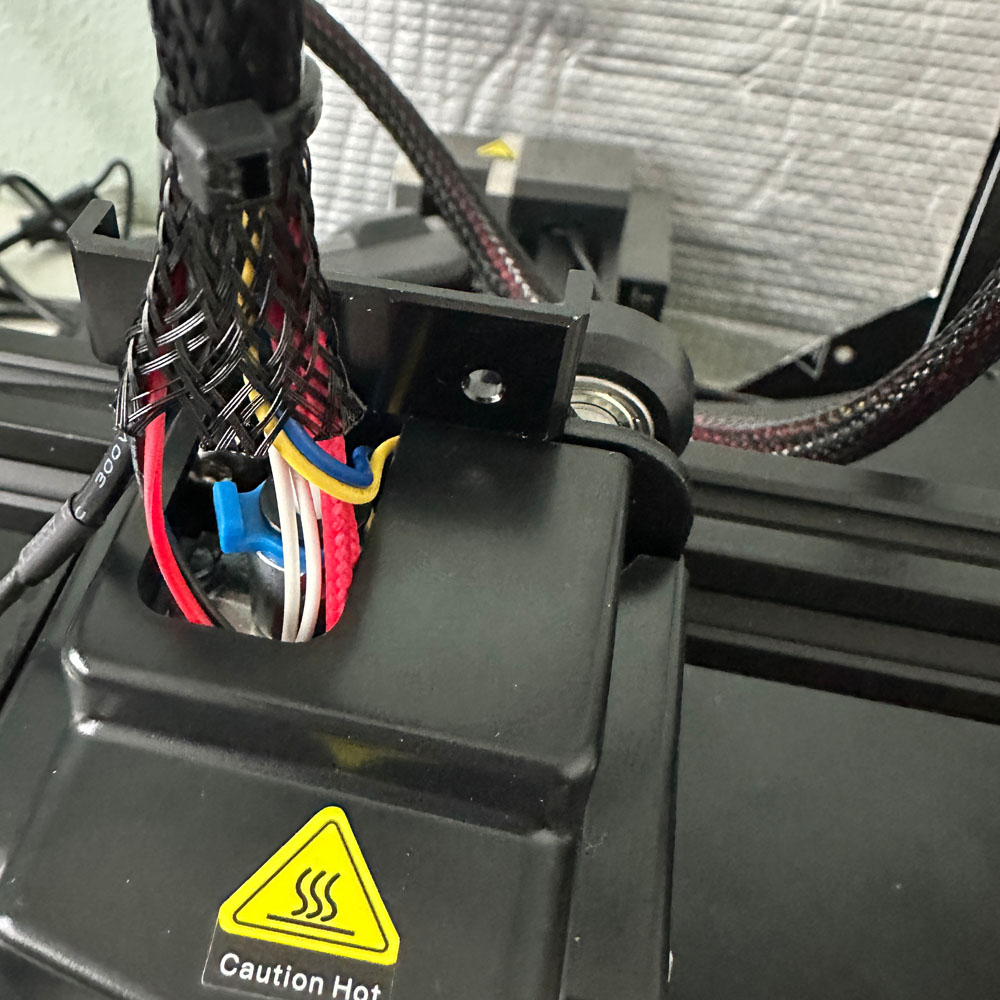

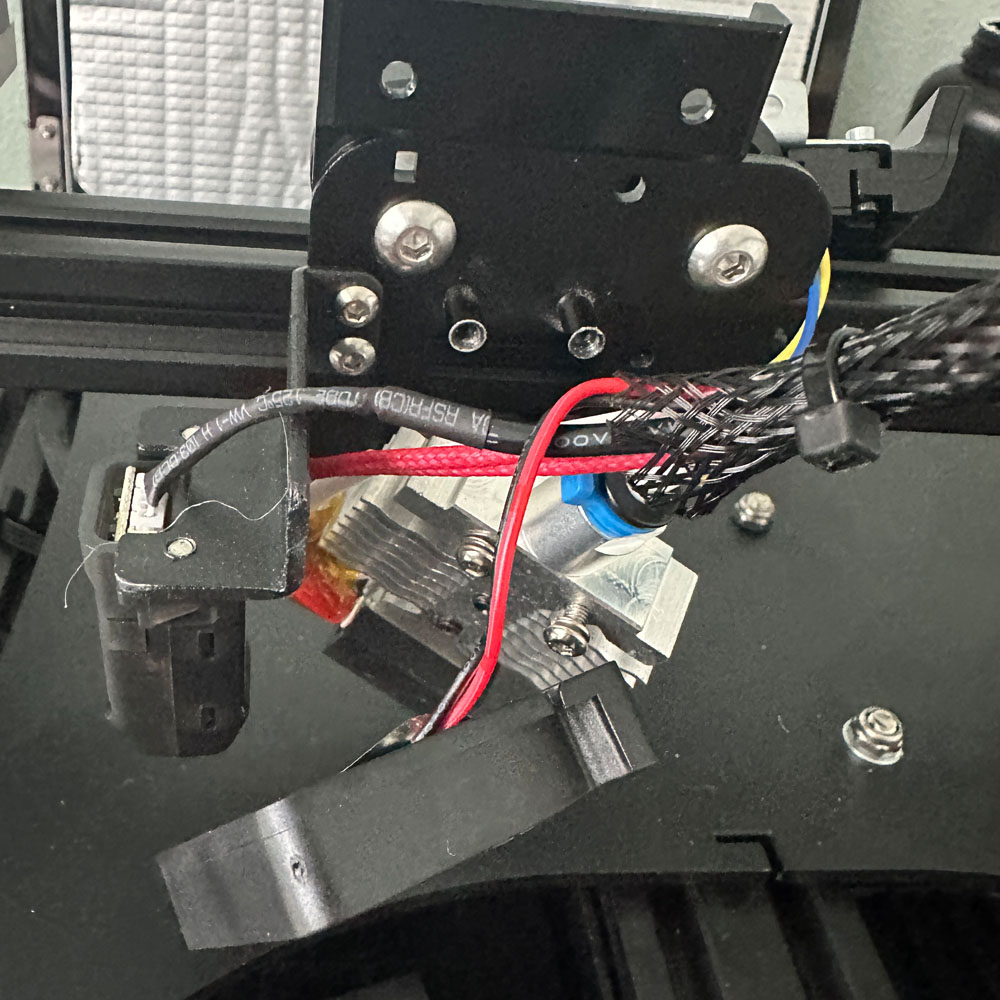

We continue with the Rebuild In Progress, Part 2, following on from the previous article in the series, Rebuild part 1. We are discarding the original backplate and incorporating new assembly hardware (correction, new back plate needed see that update here). Unfortunately, the new OEM plate was not compatible with my setup, so I will salvage the new wheels, screws, tightening washers, bolts, and spacers where possible. I quickly performed a dry-fit of all the components, including the screws, spacers, wheels brackets, probe (a black, narrow plastic piece with a probe), side fans (with yellow and blue wires), and heating element (comprised of a heater, heat sink and extruder).

For the final step, make sure to tighten the wheel screws, fan, drive belts, and extruder before installing the heating element. The order in which you do this is important, just like when removing the Bowden drive, brackets and extruder tube. We will reuse some of the old tube to guide TPU filament into the new direct drive extruder. Next, install the extruder fan (red and black wires). Now, you can unscrew the two top wheels and install the new direct drive platform, secure it, and snap on the carriage case (note: the hot side should be on top).

Next, attach the direct drive by clipping it onto the tube provided tube, then snip the tube after a fitting or two. Ensure, the fit is correct. Screw in the direct drive platform from the backside of the plate, which should be installed on the last step. After securing it, connect the direct drive motor to the main line by passing the frame platform where the old extruder motor was located (refer to the last couple of images) and place the harvested tube for the filament.

Easy, right? Part 3 will be coming shortly. We will cover that tomorrow. We need to replace the heating plate, power on the machine and change the step movement.