Gear – More Gear On The Chopping Block

What’s that in the box, ((shake)) ((shake)) what might that be? A new shipment, what is in ‘the box’ and on the bench.

Let’s start by sharing this on the big Gadget Backlog, is currently in progress, as space is somewhat limited at the moment. More information on that will be coming soon. As for batteries, I have a few Optima Red Tops ready to go, along with some outback welding where necessary. It’s fitting to mention magnetic tools and switches in this context. Yes, super strong magnets that can be switched on and off with a swift turn of the hand or a switch-type mechanism. This is a very cool item to have around the house, shop, or off-road adventures.

Angle Clamps, Mag switches and More Welding Tools

I’m curious to know if the welding community has a preference for welding square/angle holders, clamps, plunger/light switch types, magnetic holders etc., perhaps at no cost. Obviously, if you’re out on the trail, off-roading, doing trail break-fixes, integrity and rigidity might take precedence over OEM specs on angles or manufacturer measurements. When it’s time to getting your off-road rig off the trail, would something like this help to bring your efforts in line with those manufacture specs per say. Anyhow, these switch magnets might be handy to have around the shop. Various types – Angle Clamps, Magswitch Clamp, Stackable Magnets or Adjustable Angle Magnetic Welding Squares.

So, let’s discuss cover what has been unboxed… the Bloom Frother. As you know, the hand mixer needed some adjustments. A few screws, new batteries, some isopropyl alcohol… and we are back in action. You all know I’m a big coffee and tea enthusiast, but if not, that’s okay too. I like my coffee and tea with a few pinches of Sugar in the Raw, and depending on the time of day, I may add some half-and-half to adjust the temperature.

There are a few handheld frothers out there in various color and materials… the Bloom is now revived, with new batteries and ready to mix. So, I am please with the purchase for now. I will provide an update on the long-term usage of the Bloom fix. I must admin, an alternative option might be the Bodum Schimuna Whisk, which has a piqued my interest. For those of you in the market for a micro whisk/frother, the Bodum Schimuna might make a great client gift at some point.

SHURE and Aupus

Next on the Gadget Backlog, we have the SHURE MV7 USB mic! Initial thoughts – great sound, crisp dynamic tones and easy to use. Another step forward towards audio/video experiences. The microphone includes a desktop friendly microphone stand. MacOS users will need to download the SHURE Application to mix and control the external accessory. There is a bit more work involved in getting around the need to purchase additional cables, XLR adapters or fittings. Look for a deep dive, and pictures to accompany the post.

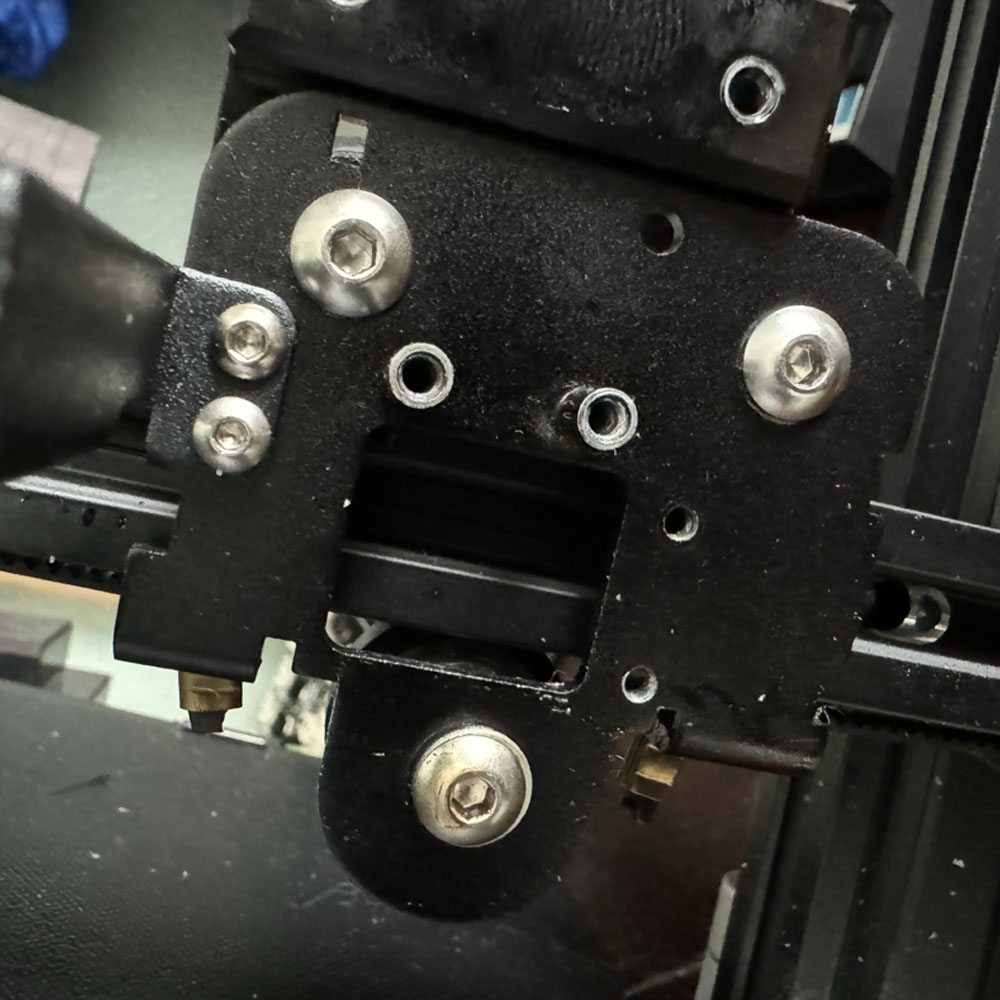

Moving on, let’s talk about ditching the air duster can for a powerful, corded air duster like the Aupus APAD15BL Air Duster. Air cans have served their purpose for many years, especially when paired with electrical-friendly wipes. While we are on the topic of air gadgets, we have more air tools coming your way – Inflators, Air Compressors, Nailers and more. The air compressor even comes with a hand air blower tool for outdoor jobs. Like the air blower, this plug-and-play air cannon offers variable speeds, cleaning tools, and filters. This small, office-friendly tool is handy to have in and around the shop as well. While we are discussing gadgets and tools for the shop/office, we are enhancing the Makey tech tool set by adding a set of Torx screwdrivers (T3 – T10) – Tekprem Torx Screwdrivers.

One downfall I’d like to mention is the integrity of the star and Torx bits. Torx and star bits are delicate and can easily get damaged. A word of caution you have to be careful with nano screws and give it time. Consider replacing the bits or the entire set with a set like these. What I’m observing is that screw lock… can be more beneficial here, but it does take a toll on the micro-bits used to drive in our unwind electronic screws. I’ll provide more feedback and comments on the Torx set and air cannon as we use those items on the bench.

D’Addario celluloid

Finally, last on our big Gadget Backlog list, we picked up a new guitar pick. Most are similar, with smooth or textured surfaces. The main problem I’m having is grip. After a few minutes, grip becomes an issue… it might be the ‘player’, but slippage is a problem. Sweat seems to be the culprit. Odd, huh? So, I’ve added a mixed bag of D’Addario Celluloid picks to the mix. The goal was to switch it up a bit and try something new. I still have a few Fender Celluloid Medium picks and Dunlop Max-Grip variety.