Lab Work – Building and Buying Parts On The Supply List

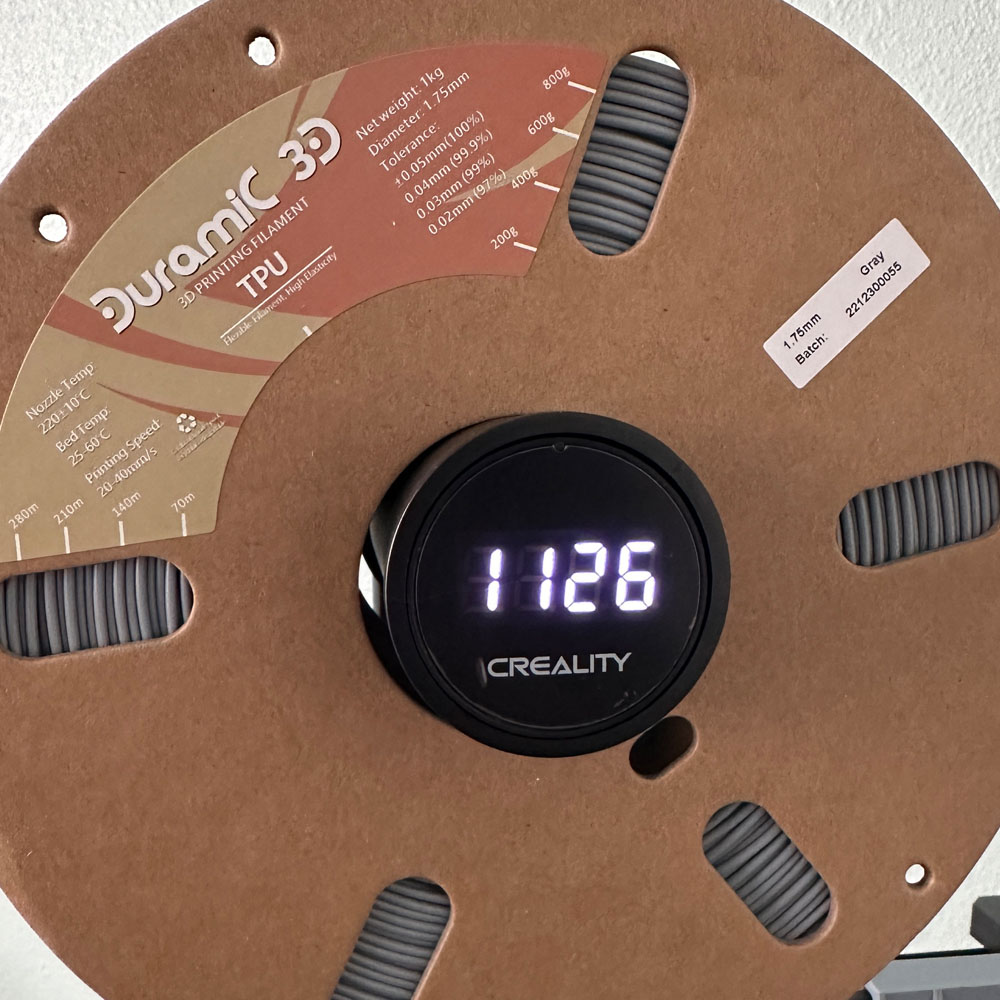

…A few more days folks, and we can start working on the TPU Direct Drive Support build. A new extruder support plate for the Ender 3 Neo Max is on its way. Not on back order, but waiting the last piece before the rebuild can begin.

Before we proceed with installing the new parts, we discovered an issue with the back support plate (including wheels and bolts) being misaligned. After the printer ‘meltdown’ a few months ago, you can see the results of that print here. The final piece needed for the rebuild is this support back plate. There is too much play and space between the assembly and guide rails. I don’t recall there being any movement between the parts. I would expect there to be little to no wiggle room in those items. However, I can almost light off the assembly housing, extruder, and back plate from the guide rails under tension. This was a clear sign that it was time to replace the guide rails under tension. think there is no or very little ‘wiggle room’/tolerance in those items. However, I can almost lift off the assembly housing, extruder, and back plate from the guide rails under tension. This was a clear sign that it was time to replace the support plate, bolts, and wheels to ensure an improved upgrade and fix.

New Build

Anyhow, all the pieces and parts have been removed from the initial purchase. We will proceed with the TPU Direct Drive Support build. So, for picture sake, we’ve got the frame, base, and guide rails and that’s it. All parts have been removed for the moment. ~It’s been about 3 weeks now, awaiting the OEM support plate. Ultimately, we are looking at a clean rebuild using OEM parts with a few upgrades (direct drive, replacing the Bowden extruder) to allow for TPU, Wood/Bamboo, Carbon, Metal, Organics and more.

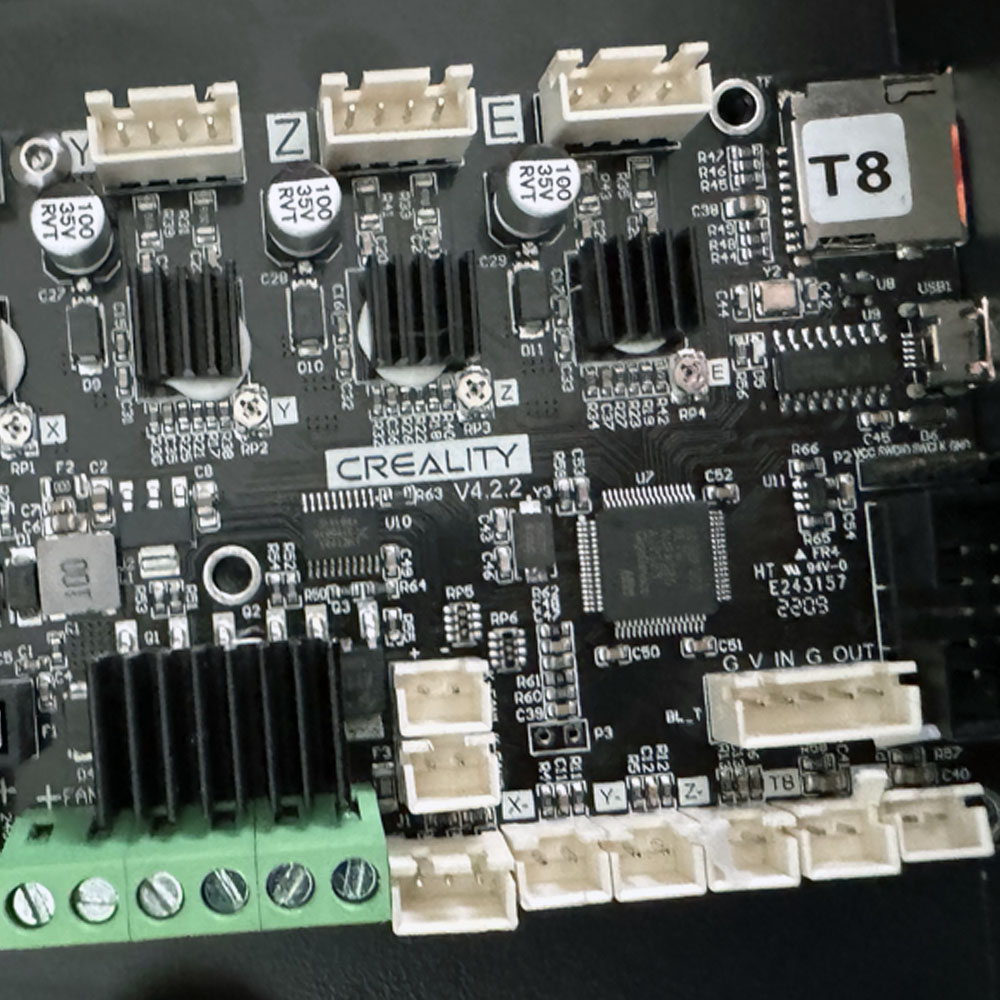

System upgrades might come later, with the goal being more power to compensate for the downforces on the extruder head in the direct drive case. Caution, there are differences between the Direct-drive and Bowden extruders, obviously advantages and disadvantages for both… maintenance and care being the most complex for the direct-drive variety.

More Filament Types

The goal with the direct-drive ‘pivot’ is to improve heat, extrusion pressure, retraction and expand the range of filament materials. For the sake of this article, I will focus on the updated advantages and disadvantages. The comparison is between more materials, heat, pressure, and variety versus maintenance which can be a lot. I personally use the break/fix method, as parts are less expensive to replace in the printer ecosystem. It may not always be the wised choice, but sometimes breaking something is necessary to understand the machine or engineering behind it. In conclusion, having spare parts on hand is helpful. Build yourself a parts bin and consider parting out used or gently used components to reduce out-of-pocket expenses. Learn how to maintain and reuse your gadgets. Remember to fail fast when working on such equipment. Short-term expenses for break-fix situations can save money in the long run when dealing with 3D printers, drones, computers, and more

Final thoughts: Parts can help you build yourself a parts bin. Need updates, board firmware, and Slicers? Download those items here for Creality Software Support. Part out used and gently used parts to cut down on out-of-pocket expenses. Learn how to maintain and reuse your gadgets. Don’t forget to fail fast, when working on such equipment. Short-term break fix expenses go along way when dealing with 3D printers, drones, computers and more.