TPU Filament, Challenges and Wins

OEM TPU

Lab Work – Various Filaments

Filament types, such as Creality TPU and various brands, can be a nightmare of a problem to have. Which filament should you purchase? What works best on the 3D printer I own? What should I do when I’m just starting out?

Cut to the point: purchase anduse what you can in context. However, when push comes to shove, the Ender Series, Prusa, and Makerbot all great choices for novices or beginners. Starting with an eBay ‘parts’ printer, might help cut down costs or consider a refurbished one.

Regardless of the product make or structure, the fine-tuning the nozzles, stability of the machine, drive system, adhesion, and filament are important. Filament might be the easiest to swap out, follower by the nozzle (noting various nozzle sizes, with most default sizes being .4mm). For hobbyists, the drive mechanism, bed/build plates, etc. may also need attention. Filament might just be an easy swap with a catch.

Like most things, filament comes with it’s own issues – additional research is required, fine tuning and testing depending on the choice of 3D printer. Let’s talk shop, about filaments, retraction (more on this in a future post). Listen, if purchasing power is a problem, meaning if you have limited funds, start by buying what you can afford, especially for those starting out in the 3D printing hobby. Do what you can to make ‘it work’. Making it work means being able to test, test, and retest. It’s a process of elimination, gradually solving problems over time. Better filaments lead to better results.

Let’s have a look

There have been many times when testing, in fact, I might venture to say, problems are related to the cost of filament and the length of time it takes the user to move from the cheaper options to the final working filament. At least in my experience of finding the right filament through testing, more than not, filament testing became a costly lesson in what not to do. So, yes, a healthy dose of testing is needed, including failure.

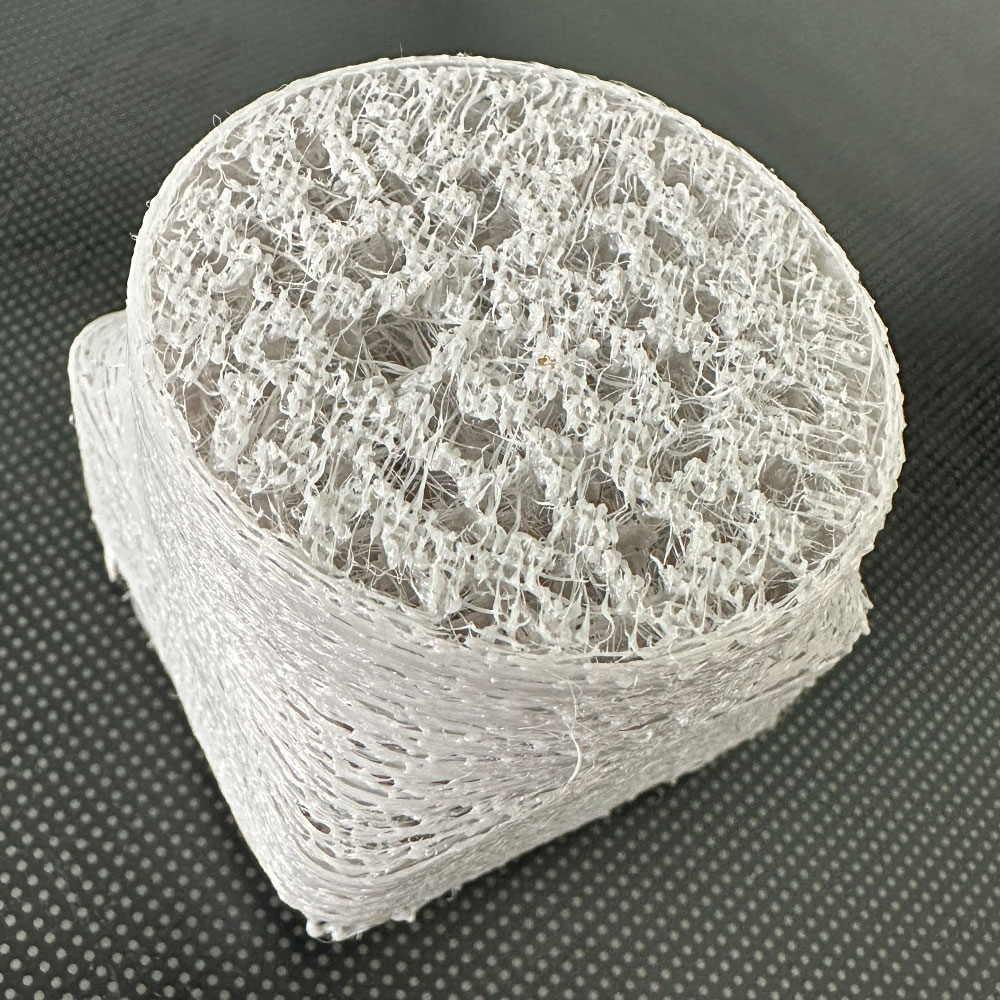

That said, I would be remiss not to highlight the value of this article, which is to help you save money on filaments, pieces, parts, and printing costs. The key takeaway is to buy and match OEM (Original Equipment Manufacturing) filaments. For example, since I have Creality printers (3 Creality printers in total), thus, I use Creality filaments like Creality TPU (Thermoplastic Polyurethane) Filament.

Lately, we’ve been looking branch out a bit, as we’ve recently added the Prusa’s i3 MK3S+ 3D Printer kit to the mix. Again, there are many options, printers, upgrades, filaments… choose wisely.

Learn More via MatterHackers

Let’s focus on what works, finding something that works for your current printer or future printer. As a hobbyist, I have stuck to the ‘happy path’ being less adventurous and mainly using PLA’s (Polylactic Acid) and TPU’s. MatterHackers does an excellent job of providing information on what’s available on the market, including types of filament, sizes, brands, and colors.

Dive in! Or maybe, expansion is on your mind, and you want to setup your own print farm – @ShopNation might be a great research to check out. Have options, which might be the biggest take away beyond testing or OEM/OEM filaments. Hey, as a hobbyist, saving some cash is good thing, there are thousands of upgrades on the market, same for the number of printers, filaments, parts, boards etc.

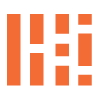

Through various testing methods, settings, set ups, printers and more, I have discovered that what matters most is what works. That is defined as success rate or success metric. Consistency, fit/finish, quality over flash and speed over quantity are key factor. For example Duramic 3D TPU is just not working in the Ender 3 Neo Max rebuild. After tearing it down, rebuilding with all updates, and getting the same result, it is clear that it is time to make a switch.

OEM Filaments and More

The switch I’m referring to here, moving from generics to OEM, worked on the PLA side of the equation. It may be a correlation perhaps, and not causation. I believe that’s the value here. A handy lesson might be to continue testing where it makes sense. Remember, “correlation does not imply or mean causation,” via Mr. Glickman. Learn more about his work via his personal website or faculty website. Or, click here – Mark Glickman – Senior Lecturer in Statistics, Director of Masters Study.

If you want to learn more about filaments, do your research. Please do look into – MatterHackers, All3dp – Filament Finds and/or @ShopNation…

I’ll leave you with this, try what you can afford, what you can afford to discard. Test and work to fine-tune your printer. Words of encouragement ‘leave no product stone unturned’. The goal is to produce high quality, consistent, and clean prints.

Find something that works 80% of the time, the old 80/20 rule. PLA is difficult bear to tweak and maintain, as is TPU and the ~approximately 14 other materials including metals, carbon fiber, wood, and nylon. The applications are endless, ranging from starter to full forge, high-strength, commercial production. The focus should be on settings, adhesion, extrusion temp, nozzle temp, surface tension, and drives – pushers… And so on, testing is our motto/mantra, testing has become a constant. Key is to find something that works well overall, so test them all. Checkin from time to time, as new posts are created daily. We will cover the Prusa tests, Creality TPU, Polycarbonate and PVA (Polyvinyl Alcohol).

Have fun, cheers

Drone Accessories

Creality TPU

TPU Weight

Duramic 3D