Rebuild, Continues Part 3

Final Assembly, Boot, Config and Print

Lab Work – Rebuild Part 3

I encountered a bit of a snag, but I am rebuilding and continuing with part 3 – working through those challenges now. For the time being, please refer to the updates above/below for part 3 updates. We will be covering more of the rebuild process, including the x/y axis bands, plate, direct drive issues, boot/reboot procedures, and reinstalling printer drivers. Additionally, we will discuss slicers, nozzles, extruder/heating element, and the latest issue, the onboard/external interface.

Breaking Through, Troubleshooting activities

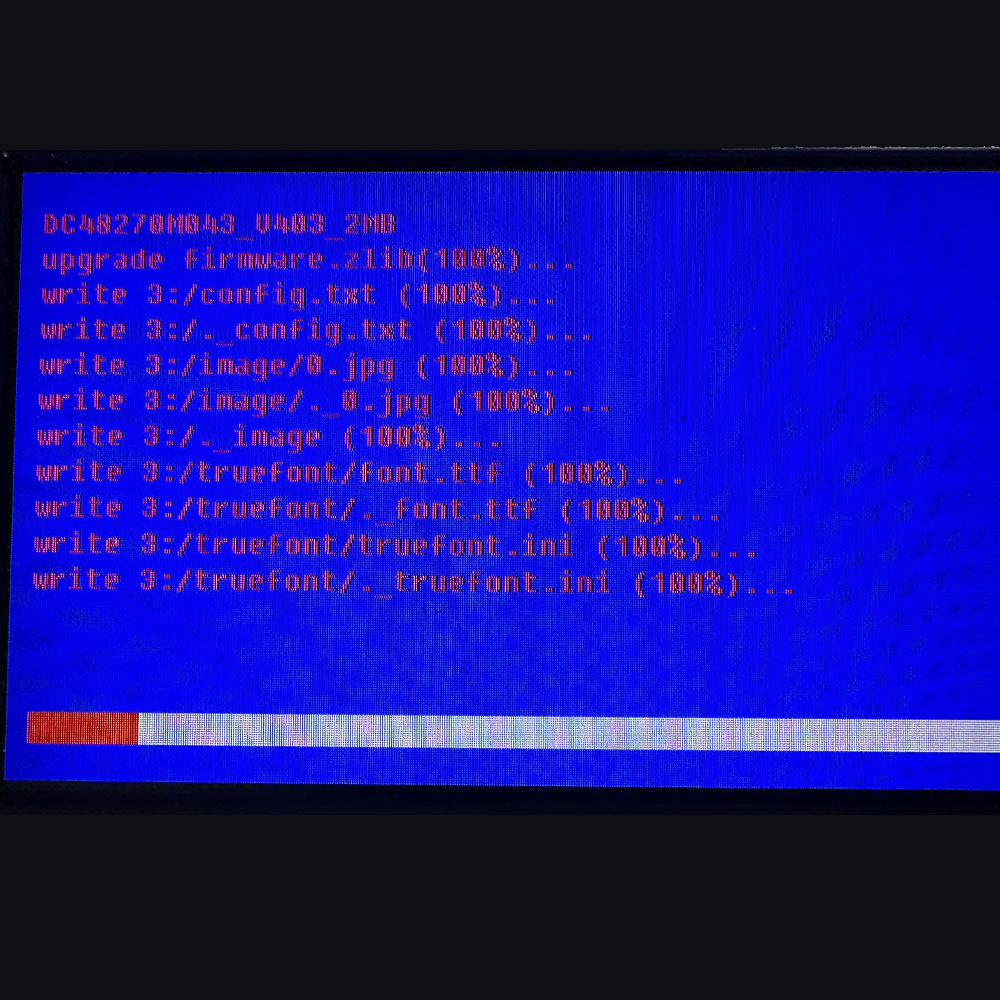

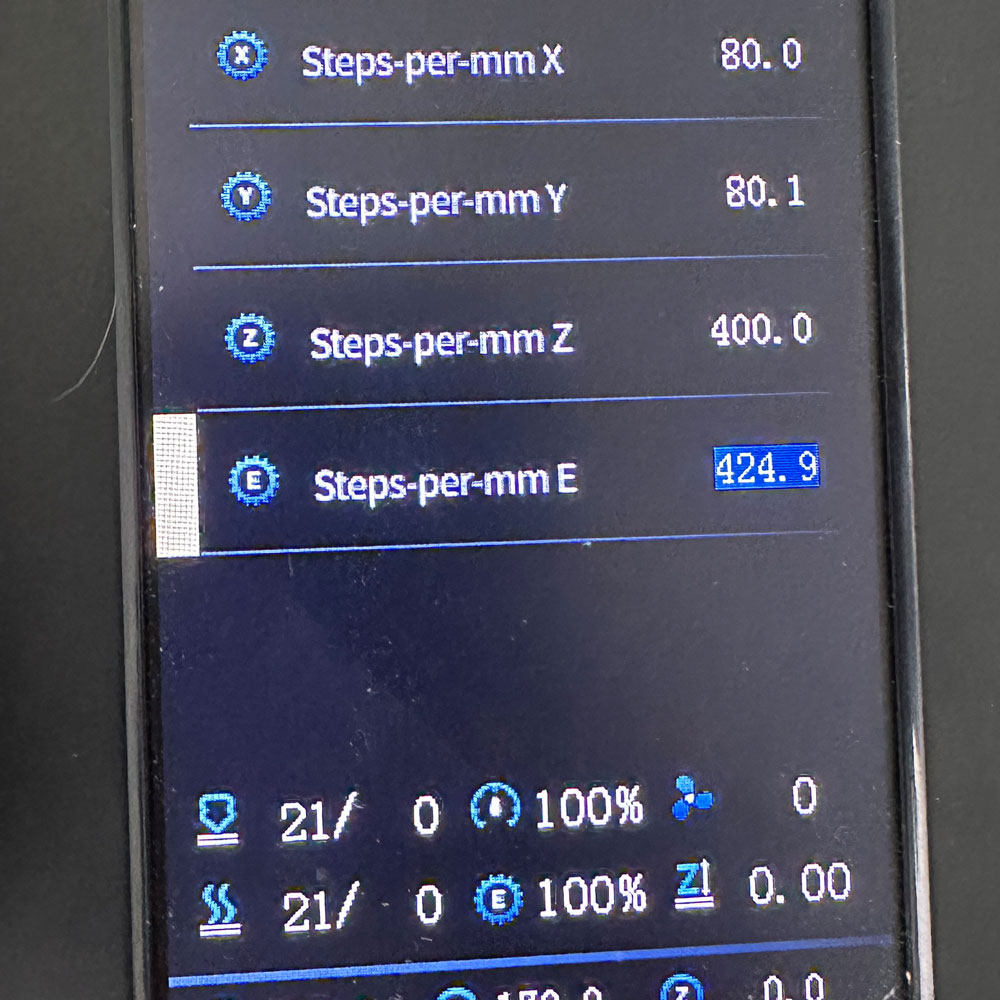

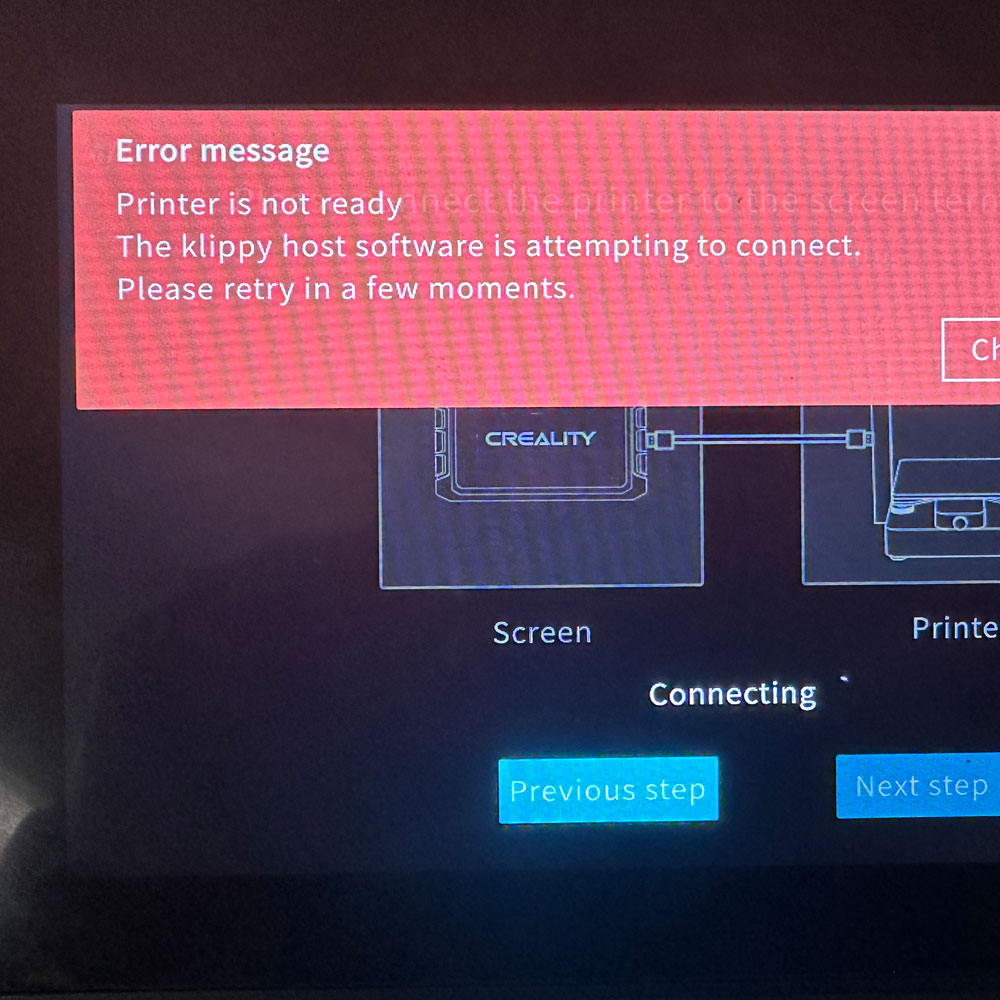

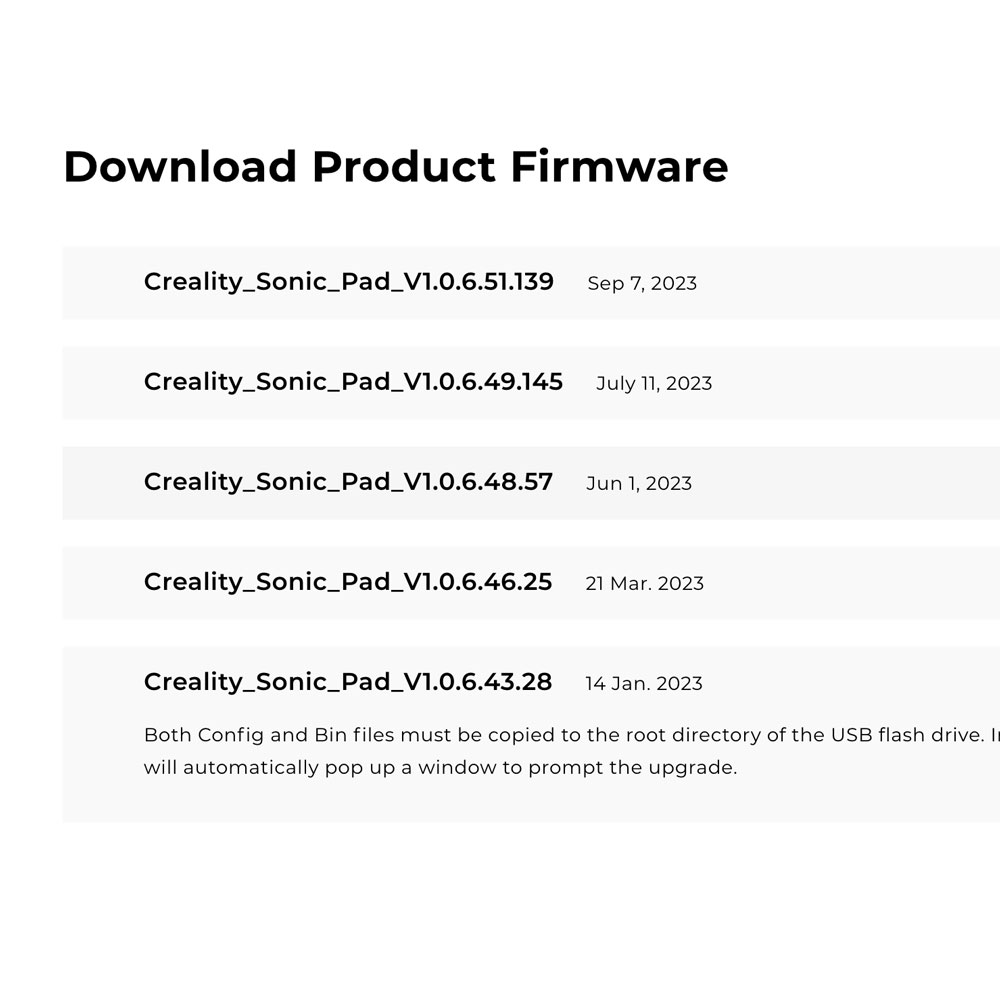

As noted in the previous build, Part 2, we are likely around 80%-90% complete at this point. We will refer to this rebuild as Part 3. We have encounteered some filament burn and melt down, as well as blockers that we will address in Part 4. Nonetheless, Part 2 was successful, and now Part 3 is also going well, with all parts functioning as expected and the boards booting as they should. The new drive and extruder are working in tandem as intended. The ‘issue, as previously mentioned, lies between the Creality Sonic Pad, printer board and connecting software. Images will be included to illustrate the challenges faced during the rebuild, including manual updates made on the printer screen, main board, and the area where we are currently stuck with the Sonic Pad. Two notable errors are the Klippy software and Sonic Pad physical connection failure, as well was filament recognition.

Out next steps will involve installing/rebuilding Klippy, testing, retesting print config files, reattaching the Sonic Pad, replacing extruder tubes, nozzles, adjusting e-Steps, home position and more, while also adding the Wifi Box 2.0. Once all of these tasks are completed and throughly vetted and tested, we will create a brief update of the build and active prints to mark these items of the rebuild list.

Got to love technology (or not), and office ‘helpers’ Zeus thought he would take a little snooze while the troubleshooting session continued throughout the day and night. The same can be said for discovery and testing, there’s no time like the present. Some folks call it the ‘grind’… I’ll leave that there for you to imagine. Is it painstakingly difficult? No. Time always plays a role, especially when speed-to-market is crucial. You have to be willing to work with what you have… Part 4 will be coming shortly, where we will cover fine tuning, steps, extrusion, adhesion and whatever else pops up in the meantime.

Drone Accessories

Print Video

Tension Bands

Secure Bands

Waiting

LCD SD Card

Clean Build Plate

Install Firmware

Power On

E Stepper

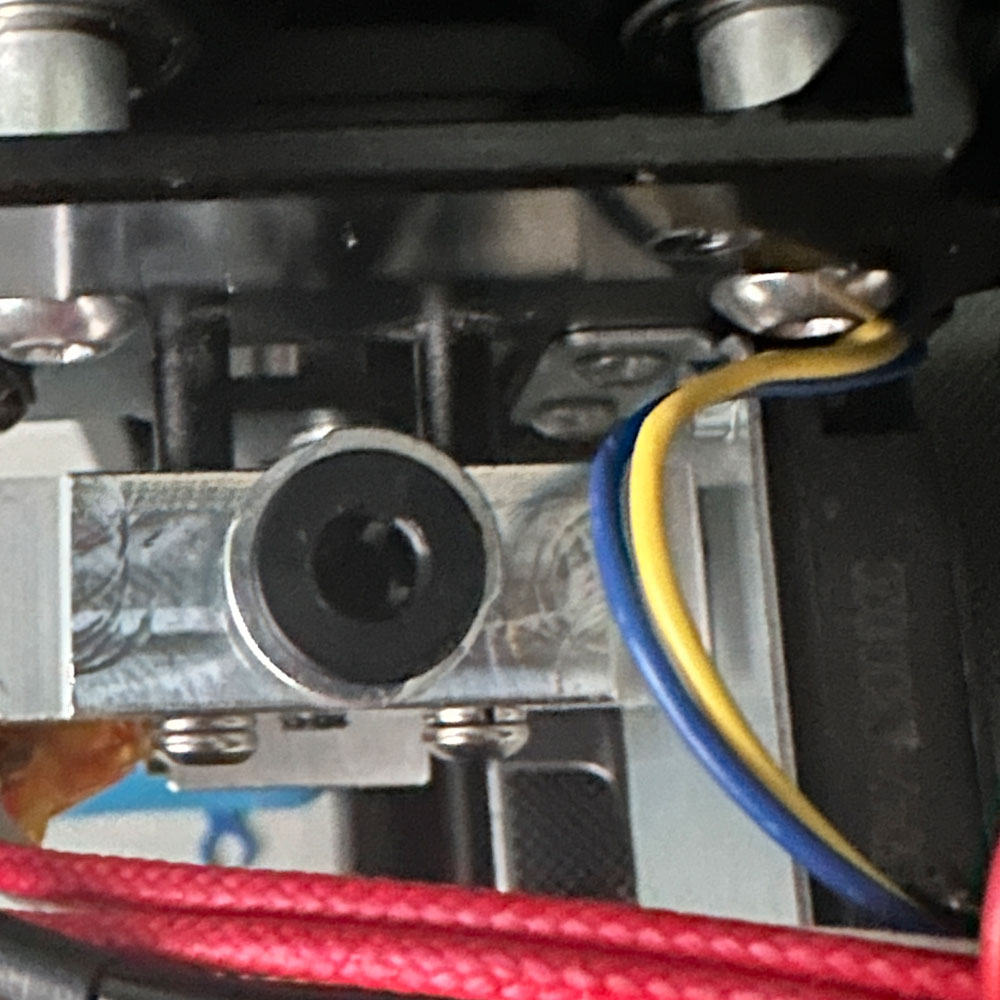

Connection Error

Firmware Selection

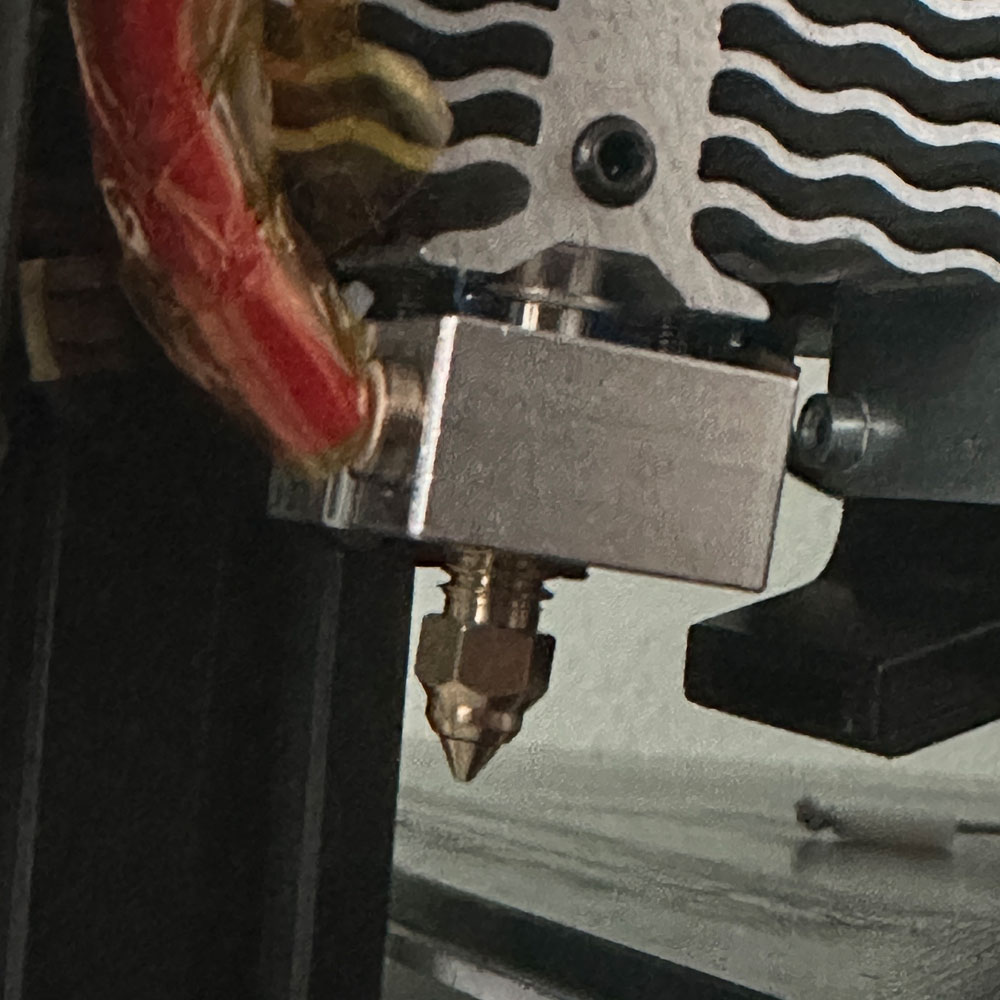

Extruder

Hot End